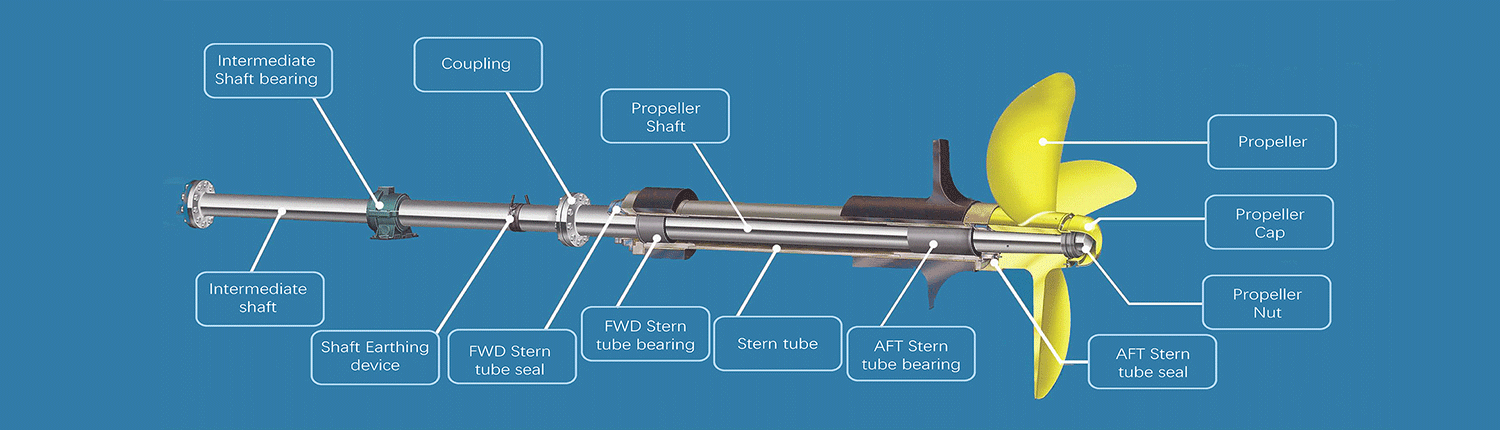

Propeller Stern Shaft

The stern shaft materials have passed EN10204-3.1 certification, covering various grades of: low carbon steel, alloy steel, stainless steel, ductile iron, aluminum alloy, copper alloy, titanium alloy.

The main processes are: free forging, die forging, rolling ring, high pressure casting, centrifugal casting, normalizing, quenching and tempering, solution treatment, aging treatment, carbonitriding, turning, milling, drilling, grinding, hobbing, high frequency quenching, galvanizing, chrome plating, anodizing, powder spraying and other processes.

The propeller shafts length: Max 16000mm,max dimeter is 500mm, single piece weight: Max 16 Tons, at the same time we are good at terminal machining of complex products, dimension accuracy: Min 0.01mm, roughness: Min Ra0.6.

Boat Stern Shaft

Specification:

1.Material:H13,4130,4140,4150,4340,1035,1045,EN9,EN19,EN24,EN31,51200,SUJ2,100Cr6,K310,34CrNiMo6,36CrNiMo4,42CrMo4,86CrMoV7, C35E, C40E, C45E, etc.

2.Hardness: HB240-320

3.Ultrasonic Test: Sep 1921-84 – Test Group 3 Class D or ASTM A388 – FBH max 4mm

4.Forging reduction ratio: ≥4

5.Manufacturing process: steel ingot→forging→rough machining→QT→2th rough machining→finishing machining→packing→delivery

6.Quality required: Surface defect and decarburization shall be free. All dimensions are 100% OK.

7.Packing: wooden box or metal pallet for protection against rust and damage.

8.Quality Management Certification: ISO 9001:2008.

| Product Name | Specification | Main Materials |

| marine propeller shaft | Dia.80~ Dia.500mm

Length≤16000mm |

H13,4130,4140,4150,4340,

EN9,EN19,EN24,EN31,etc |

the marine propeller shaft can be strictly examined by chemical composition, tensile strength, yield strength, reduction of area, impact at low temperature, intergranular corrosion, hardness, metallographic, NDT, size, static balance etc performance parameter.