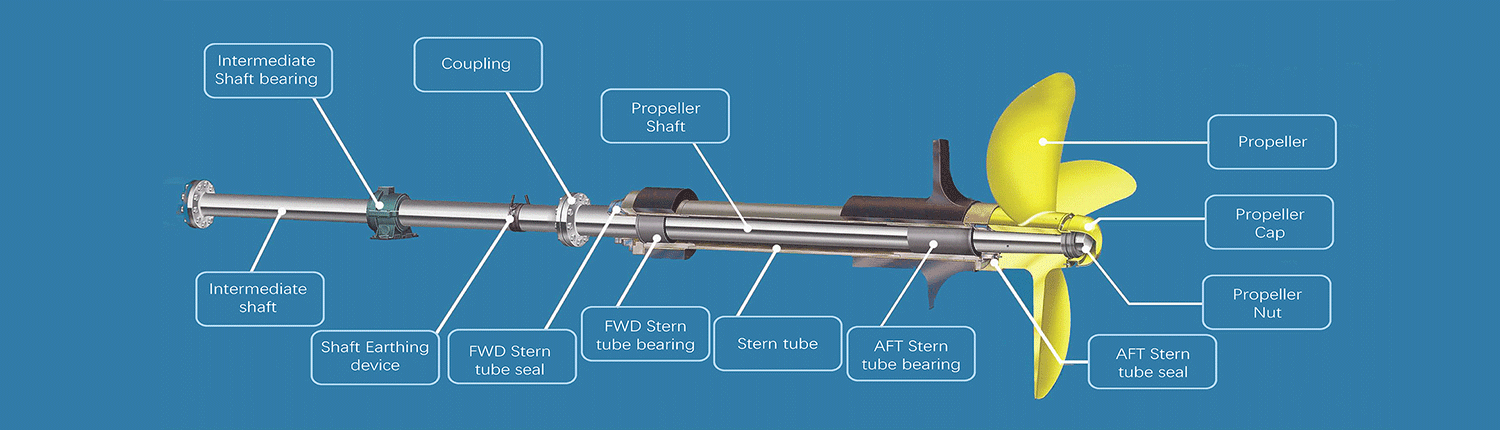

Shafting System Contershaft

The intermediate shaft, covering various grades of: low carbon steel, alloy steel, stainless steel, ductile iron, aluminum alloy, copper alloy, titanium alloy.

The main processes are: free forging, die forging, rolling ring, high pressure casting, centrifugal casting, normalizing, quenching and tempering, solution treatment, aging treatment, carbonitriding, turning, milling, drilling, grinding, hobbing, high frequency quenching, galvanizing, chrome plating, anodizing, powder spraying and other processes.

Counter shaft/Intermediate shaft for boat

The intermediate shaft for boat can be strictly examined by chemical composition, tensile strength, yield strength, reduction of area, impact at low temperature, intergranular corrosion, hardness, metallographic, NDT, size, static balance etc performance parameter.

The intermediate shaft forging is one of the typical forgings frequently encountered in machines.It is mainly used to support transmission parts, transmission torque and load.Shaft forgings are rotary forgings, whose length is greater than the diameter. They are generally composed of concentric shaft outer cylinder, conical surface, inner hole and thread and corresponding end face.According to the different shape of the structure, the shaft forgings can be divided into optical shaft, step shaft, hollow shaft and crankshaft.

| Materials | Steel alloy,34CrMo4, 42CrMo4,S45C, 40CrNiMoA ,20CrNiMoA34CrNiMo6,36CrNiMo4, 36NiCrMo4, 40NiCrMo6 |

| Structure | Forging&Casting |

| Process | Lathing, milling,grinding,drilling |

| Accepted tolerance | Less than 0.05 |

| NDT Standard | AISI,EN, |

| Diameter | According to the drawing |

| Weight | Max 40 ton |