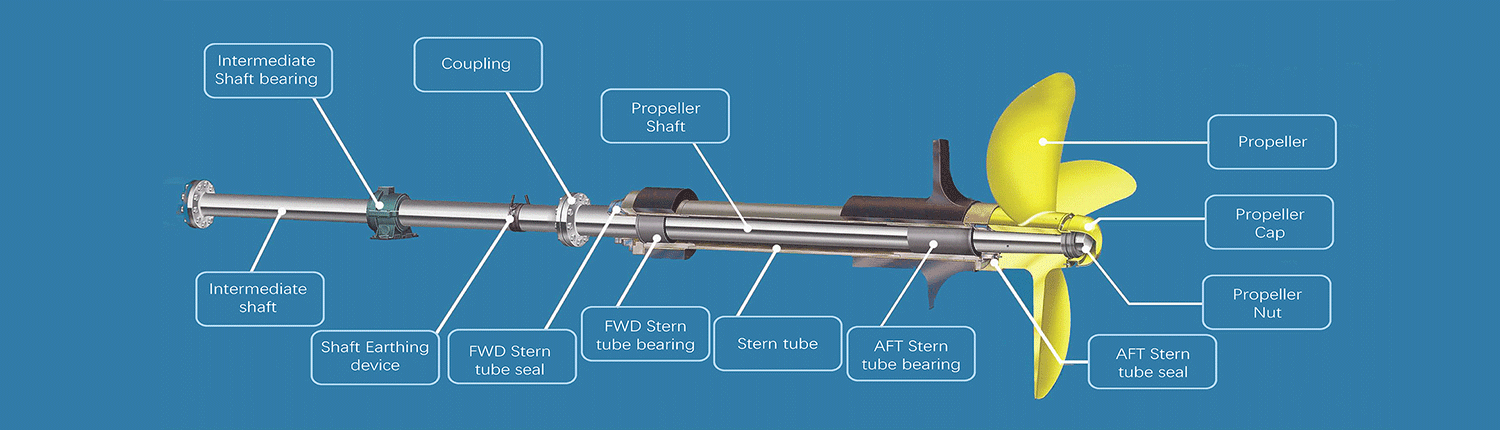

Shafting System Polymer Bearing

The propeller shaft bearing is applied in stern fin and intermediate shaft bearing of all kinds of ships,whose materials have commonalities of all the gilding bearing and are applied in all the open lubricating systems and closed lubricating systems.It is a polymer material, as the differences of using fields and lubricating mediums,multi-copolymer can meet.

Material propeller shaft bearing: high polymer material, rubber

Dimensions: designed according to the shaft.

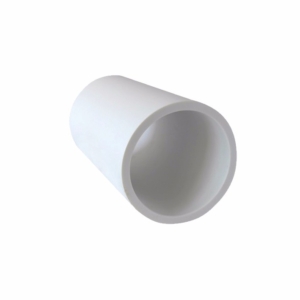

High polymer bearing

The high polymer is widely used in the bearing for ships’ stern tube and rudder. It can be used for all kinds of vessels around the world. It is the main material for the bearings. The High Polymer Bearing material is a co-polymer high polymer material, with all generalities of sliding bearings, suitable for open and closed lubrication system can meet the needs of a variety of environment. The high polymer bearing is with high abrasion resistance, multi-purpose and stability. It brings remarkable economic benefits to ship owners and shipyards and brings great social benefits for marine bearing materials domestication.

Type: FWD High Polymer Bearing, AFT High Polymer Bearing, Water Lubrication Bearing, Oil Lubrication Bearing

Physical & Mechanical Properties of High Polymer Bearing

| PROPERTY | UNITS | RESULT |

| Density | g/cm3 | 1.1567 |

| Hardness | HRL | 81.1 |

| Tensile Strength | MPa | 90.7 |

| Compress Intensity | MPa | 114.5 |

| Flexural Strength | MPa | 114.7 |

| Coefficient of Thermal Expansion | 1/°C | 8×10-5 |

| Thermal Conductivity | W/MK | 0.33 |

| Soft Point | °C | ≥220 |

| 20°C 24h Water Absorption | % | ≤0.6 |

| 20°C 24h Oil Absorption | % | ≤0.2 |

Technical Parameter for the High Polymer Bearing

| Shaft Dia. | Flume No. | Flume Angle (Degree) | Flume Width | Flume Depth | Water Flow (L/min) |

| 60-79 | 5 | 60 | 5 | 4 | 12 |

| 80-119 | 7 | 45 | 6 | 5 | 18 |

| 120-159 | 7 | 45 | 7 | 6 | 24 |

| 160-199 | 7 | 45 | 8 | 7 | 30 |

| 200-249 | 7 | 45 | 9 | 8 | 38 |

| 250-299 | 7 | 45 | 10 | 8 | 45 |

| 300-349 | 8 | 40 | 10 | 8 | 53 |

| 350-399 | 8 | 40 | 11 | 8 | 60 |

| 400-499 | 9 | 36 | 12 | 8 | 75 |

| 500-599 | 10 | 33 | 13 | 9 | 90 |

| 600-699 | 11 | 30 | 13 | 9 | 105 |